We are Leading Company

Fastest repair service with best price!

Fastest repair service with best price!

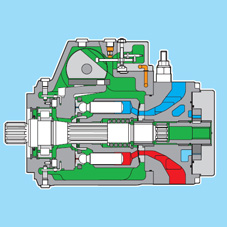

we are DISTRIBUTORS for control systems hydraulic or pneumatic and its components like pumps and valves , motors , power units and seals for this components also spare parts , pipes and fittings highly experienced with Bosch Rexroth , hydac .

supply and repair hydraulic cylinders design and manufacture hydraulic power units all sizes and all powers available. supply hydraulic filters and filter elements , measurement instruments and indicators, accumulators.

Pre-commissioning, cleaning, and flushing of hydraulic and lubrication oil systems is employed to ensure that new rotating and hydraulic equipment will start up and operate as designed, significantly reducing the potential for premature failure.

Contaminants such as water, rust, loose scale, weld slag, sand, dirt, and oils are removed from the system with a proper preoperational cleaning, reducing the wear, scoring, and damage bearings, control valves, instrumentation, and critical operating systems are subjected to. Insoluble particles can become trapped in the bearings of rotating equipment and cause significant damage. The dynamic oil film thickness in rotating bearings can be less than a micron, so it is imperative to remove particulate from lubrication systems down to a microscopic level. The cleaning process is conducted in three stages: removal of oils and varnishes, velocity flushing to remove debris, and the introduction and filtration of the lubrication oil. It is not unusual for the actual system oil to contain significant particulate, which must also be removed to prevent damage to the operating equipment. For this reason, any oil introduced into the system after flushing must be filtered to a stringent specification dictated by the equipment vendor.

When performing a cleaning job, GCS Energy designs the flushing paths in loops to maximize flow rates throughout the system. It is important that all parts of the system see turbulent flow regimes with a Reynolds number in excess of 4000.

GCS Energy utilizes external flushing equipment, which has been designed by our engineers to perform circulation, heating, and filtration of oil systems. This external equipment can provide higher flow rates than the equipment onboard the installed oil system. It is also capable of controlled system heating, resulting in significantly reduced flushing times and cost for the equipment operator.

the GCS skid allows the flexibility and ease of installing a variety of sizes of filter media to target debris based on their dimensions. A reverse flow manifold—integral to the skid—allows the system to be flushed in either direction simply by manipulating four valves.

During the flushing of systems, critical components are usually bypassed to prevent debris from becoming trapped. For example, the bearing housings on lubrication systems are typically bypassed to avoid having particulate drop out of the bearings. It is also advantageous to bypass the oil reservoirs, as they allow any particulate picked up in the cleaning flow to be deposited at the bottom of the system. The oil reservoirs can be cleaned by hand using clean, lint-free rags.

EXAMPLEApplications for lubrication and hydraulic oil flushing include:

Flushing of hydraulic and lubrication oil systems is employed to ensure that new rotating and hydraulic equipment will start up and operate as designed, significantly reducing the potential for premature failure. Maintenance and downtime on equipment can be minimized by performing an effective system cleaning during commissioning and following maintenance and repair services. Any facility that has a low tolerance for equipment failure will find this service key to their preventative maintenance program.

GCS provides a large range of fluid filtration services, from ensuring large particulate is filtered out of testing OIL to providing reverse osmosis filtration for plant process OIL.We also provide microscope particle analysis of filtered fluid to guarantee that it meets the customer's cleanliness standards, including (but not exclusive to) ISO 4406 and NAS 1638.

© 2021 COPYRIGHTS GCSI